Services

Your Partner in Engineering Excellence

Services We Provide

We design, engineer, and build precision parts, machines, and assemblies for industries that need reliability—semiconductors, aerospace, industrial, and government.

Introduction

NSB offers design, engineering, fabrication, and machining services across mechanical, electronics, and sheet metal disciplines.

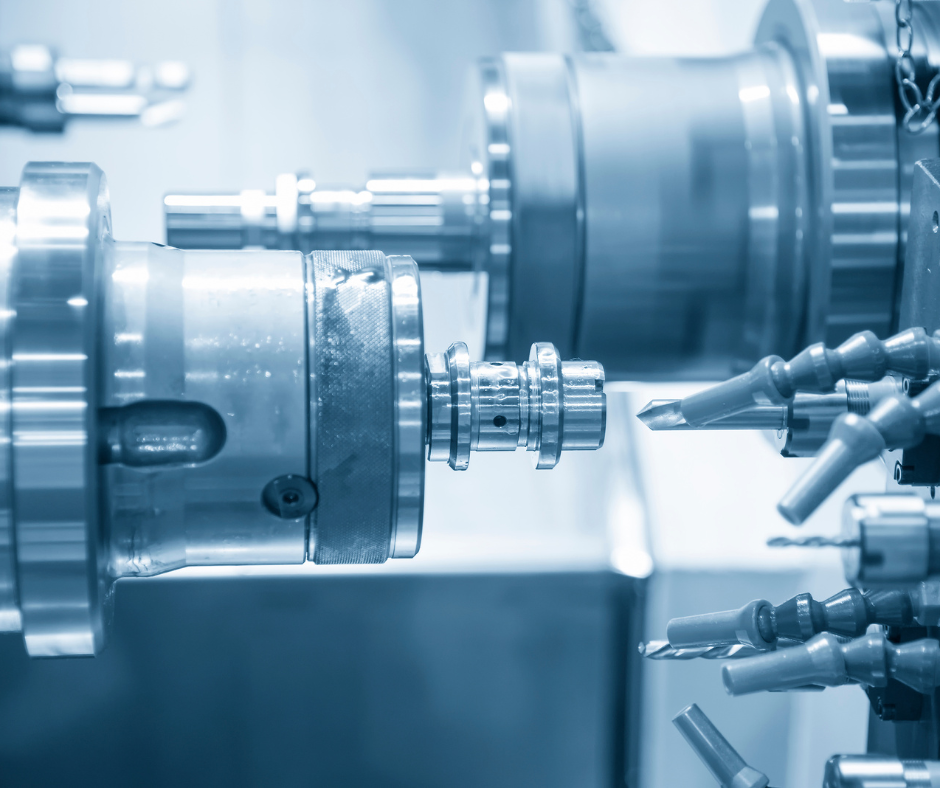

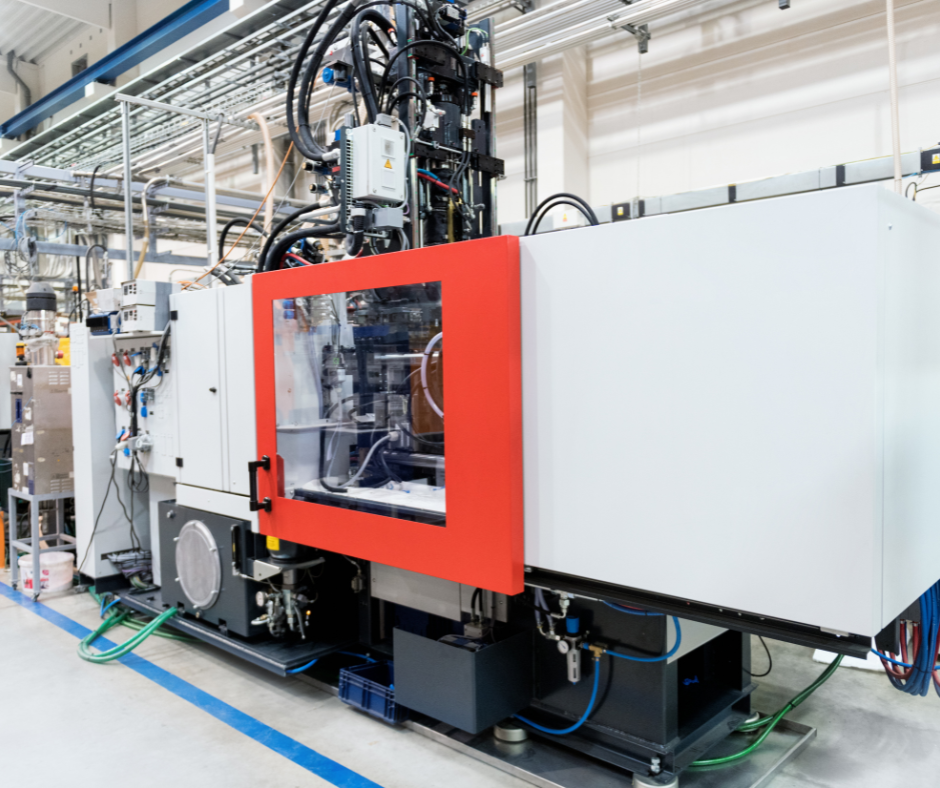

Mechanical Division

Our Mechanical Division provides design, improvement, and reverse engineering of jigs and fixtures. We also produce aerospace parts, OEM localized components, and direct machine parts. The division supports robotic systems and builds customized automated machines based on client specs.

Sheet Metal Fabrication

We fabricate sheet metal products such as storage racks, lockers, cabinets, and working platforms. This includes elevator doors, jambs, and decorative wall panels. We handle laser-cut, precision-formed parts for both functional and architectural use.

Electronics Division

Our Electronics Division handles PCB design and fabrication, board assembly, and circuit reverse engineering. We develop automation systems and provide on-site technical support for installation, troubleshooting, or process upgrades.

R&D and Gov’t Projects

We work with government agencies and research institutions on special projects, including salt processing machines, aerospace hardware for microsatellites, military shielding equipment, and mobile food processing units .

Other Capabilities

We offer a range of finishing and inspection services including anodizing, plating, powder coating, laser marking, polishing, and tool balancing. We also use material analysis tools like XRF for quality verification.